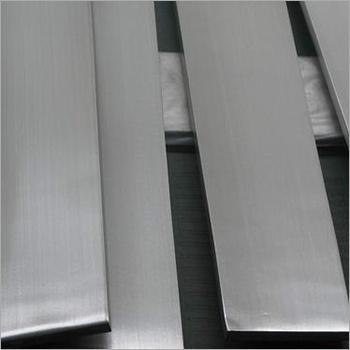

4140 Bright Bars

62 INR

Product Details:

- Steel Type Alloy Steel

- Technics Cold Drawn / Peeled / Polished

- Shape Round, Square, Flat, Hexagonal

- Tolerance H9, H10, H11 or as per customer specifications

- Application Automotive, Construction, Machinery Manufacturing, Oil & Gas, Shafts, Gears, Fasteners

- Material Alloy Steel

- Standard ASTM A29/A29M, AISI 4140, DIN 1.7225, JIS SCM440

- Click to View more

X

4140 Bright Bars Price And Quantity

- 62 INR

- 500 Kilograms

4140 Bright Bars Product Specifications

- Automotive, Construction, Machinery Manufacturing, Oil & Gas, Shafts, Gears, Fasteners

- Alloy Steel

- ASTM A29/A29M, AISI 4140, DIN 1.7225, JIS SCM440

- 4140

- Bright Drawn / Polished / Peeled / Turned

- Bright Bar

- Round: 10 mm to 100 mm, Square/Flat: 10 mm x 10 mm to 80 mm x 80 mm, Custom cut lengths available

- 6 mm to 100 mm (depends on shape and application)

- Cold Drawn / Peeled / Polished

- Alloy Steel

- Round, Square, Flat, Hexagonal

- H9, H10, H11 or as per customer specifications

4140 Bright Bars Trade Information

- 100000 Kilograms Per Month

- 1 Days

Product Description

With having an ability to offer the best, we are engrossed in manufacturing, exporting and supplying an excellent array of 4140 Bright Bars. The offered bar is widely demanded among our clients for construction of various machines and equipments by doing drilling and threading on this bars. This bar is round in shape and manufactured using best quality raw materials and upgraded machines to maintain its uniform diameter. Also, clients can avail this 4140 Bright Bars at pocket friendly prices.

Features:

- Uniform diameter

- Excellent strength

- Heavy weight

- Rust proof coating

Specifications:

-

Size: 3mm to 100mm

-

Length: 1000mm to 6000mm

Superior Alloy Steel Solution

4140 Bright Bars are crafted from top-grade alloy steel, making them a preferred choice for industries requiring components with robust mechanical properties and smooth finishes. Available in various shapes and sizes, they offer flexibility for diverse engineering applications.

Tailored Mechanical Performance

These bars are supplied in an annealed, quenched, and tempered state as needed, meeting or exceeding standards like ASTM A29/A29M, AISI 4140, DIN 1.7225, and JIS SCM440. Their controlled hardness and strength ensure optimal performance in high-stress environments.

Precision and Versatility

With tight tolerances (H9, H10, H11 or as specified) and options for custom cutting and surface treatments, 4140 Bright Bars easily integrate into automotive, construction, and manufacturing processes. Their excellent machinability streamlines production while maintaining strength.

FAQs of 4140 Bright Bars:

Q: How are 4140 Bright Bars manufactured to achieve a bright, smooth surface finish?

A: 4140 Bright Bars undergo cold finishing techniques such as drawing, peeling, grinding, or polishing to produce a bright, smooth surface. These processes enhance dimensional accuracy and appearance, making the bars suitable for applications that require close tolerances and fine finishes.Q: What are the typical applications for 4140 Bright Bars?

A: These bright bars are widely used in automotive components, machinery manufacturing, construction, oil & gas equipment, as well as in the production of shafts, gears, and fasteners due to their strength, machinability, and durability.Q: When should I choose annealed versus quenched and tempered 4140 Bright Bars?

A: Choose annealed bars for applications requiring ease of machining and moderate strength. For parts needing higher tensile and yield strength, select bars that are quenched and tempered. Specify your requirements during order placement for the appropriate heat treatment.Q: Where can custom dimensions and tolerances be specified for 4140 Bright Bars?

A: Custom sizes and tolerances can be requested at the time of order. These bars can be supplied in round, square, flat, or hexagonal shapes with thicknesses and lengths tailored to your project needs, ensuring compatibility with a wide range of engineering requirements.Q: What is the process for ensuring good machinability in 4140 Bright Bars?

A: The bars are first annealed or suitably heat-treated to achieve an optimal hardness level, typically 197-237 HBW (annealed). This, combined with their smooth, bright surface finish, ensures they deliver very good machinability for various manufacturing processes.Q: How does the corrosion resistance of 4140 Bright Bars compare to other steel types?

A: 4140 Bright Bars offer moderate corrosion resistance, suitable for most general applications. However, they are not recommended for highly corrosive environments unless protective coatings or treatments are applied, as they may not withstand aggressive chemical exposures.Q: What are the benefits of using 4140 Bright Bars for automotive or machinery manufacturing?

A: Using 4140 Bright Bars provides a combination of high strength, reliable hardness, good machinability, and dimensional precision, all of which are vital for producing durable components in automotive and machinery applications with consistent quality.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email