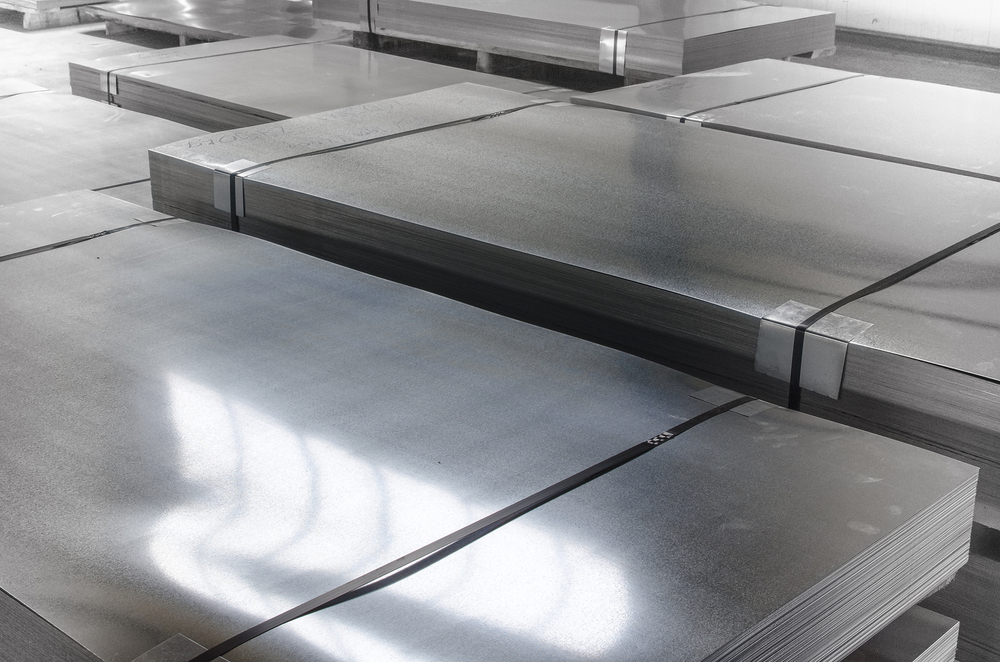

High Manganese Steel Plates

200.00 - 350.00 INR

Product Details:

- Material Composition % Mn: 12-14%, C: 0.80-1.40%, Si: up to 0.8%, P: max 0.07%, S: max 0.03%

- Size Custom as per requirement; standard up to 2500mm x 6000mm

- Corrosion Resistant Moderate, not primary feature

- Heat Resistance Yes

- Hardness 200-220 BHN (in as delivered condition)

- Coating Type Uncoated or custom corrosion protective coating available

- Product Form Sheet / Plate

- Click to View more

X

High Manganese Steel Plates Price And Quantity

- 200.00 - 350.00 INR

- 500 Kilograms

High Manganese Steel Plates Product Specifications

- Metallic grey

- 850-1100 MPa

- X120Mn12 / ASTM A128 Grade

- Yes

- Depends on plate dimensions and thickness

- High Manganese Steel Plates

- 12-14% Manganese Steel (X120Mn12, Hadfield Steel)

- N/A (Rectangular plates)

- Sheet / Plate

- Hot rolled, can be supplied with ground finish

- Uncoated or custom corrosion protective coating available

- 200-220 BHN (in as delivered condition)

- Approx. 12-14% Mn, 0.80-1.40% C, balance Fe

- Yes

- Hot rolled, untreated or ground finish

- Moderate, not primary feature

- Rectangular

- 3mm to 50mm

- Heavy-duty impact and abrasion environments

- Custom as per requirement; standard up to 2500mm x 6000mm

- Wear resistant applications, construction machinery, mining industry, railways, cement plants, earthmoving equipment

- Mn: 12-14%, C: 0.80-1.40%, Si: up to 0.8%, P: max 0.07%, S: max 0.03%

- ASTM A128 / DIN X120Mn12 / EN10083

- Custom sizes available; typical sheet sizes: 2500mm x 6000mm

- Steel Plate

- Alloy Steel (High Manganese)

High Manganese Steel Plates Trade Information

- 100000 Kilograms Per Month

- 1 Days

- Yes

- Free samples available with shipping and taxes paid by the buyer

- Middle East, Western Europe, Central America, Africa, South America, Asia, Eastern Europe, North America, Australia

- All India

Product Description

We are ranked as one of the noteworthy manufacturers, exporters and suppliers of High Manganese Steel Plates. Manufactured by our experts using quality approved steel, the offered plates are made available in various sizes. The provided plates are extensively used in mechanical, civil and construction industry for making conveyor parts, grizzly bars, truck bodies, etc. We are having a brilliant team of quality controllers who rigorously check these plates to ensure their high strength. Furthermore, clients can purchase these High Manganese Steel Plates at industry leading prices.

Features:

Features:

- Corrosion resistance

- Sturdy construction

- Dimensional accuracy

- High strength

Outstanding Impact and Abrasion Resistance

Built with a high manganese content, these steel plates showcase excellent resistance to severe impact and wear, outperforming standard steel in demanding industries. This property ensures durability and long service life, making them an optimal choice for equipment exposed to substantial mechanical stresses in mining, railways, and earthmoving sectors.

Custom Dimensions and Flexible Supply Options

Supplied in sheets, cut-pieces, or bespoke shapes, high manganese steel plates are available as per your unique project requirements. Standard plate sizes reach up to 2500mm x 6000mm, with thickness options from 3mm to 50mm. Detailed customization, including edge condition and surface finish, guarantees seamless integration into your applications.

Safe Handling and Storage Guidelines

Given their inherent toughness and weight, its essential to handle and machine these steel plates with protective equipment. To preserve quality, plates should be stored in dry environments, avoiding moisture contact that can affect surface condition. Suppliers offer delivery in as rolled or annealed states to match your fabrication needs.

FAQs of High Manganese Steel Plates:

Q: How are High Manganese Steel Plates best cut and joined?

A: Due to their tough composition, high manganese steel plates are challenging to machine and are preferably processed through cutting and welding. Use suitable cutting tools for optimal results and adhere to recommended welding procedures to maintain material integrity.Q: What applications benefit most from using High Manganese Steel Plates?

A: These plates are exceptionally well-suited for environments where high impact, friction, and abrasion are expected. Typical applications include heavy-duty components in construction machinery, mining equipment, railway crossings, cement plants, and earthmoving tools.Q: When should I choose high manganese steel over regular steel?

A: Select high manganese steel plates when substantial resistance to wear and mechanical impact is critical. They excel in situations where the primary concerns are durability and service life under tough operational conditions, especially at elevated temperatures up to 400C.Q: What are the storage and safety requirements for these plates?

A: Store these plates in a dry area to prevent corrosion and deterioration of uncoated surfaces. During handling and machining, always use appropriate safety gear due to the plates high toughness and potential sharp edges.Q: How can I purchase customized sizes or edges for my project?

A: Suppliers and manufacturers offer high manganese steel plates in custom sizes, shapes, and edge conditions. You can specify your requirements, including dimensions and finish, at the time of order. Minimum quantity depends on the suppliers policy.Q: What are the main benefits of using high manganese steel in wear-resistant environments?

A: The primary advantages are exceptional impact resistance, longevity under abrasion, and the ability to retain toughness even at elevated temperatures. These properties significantly reduce maintenance downtime and replacement costs for critical components.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email