HSS M35

50 INR

Product Details:

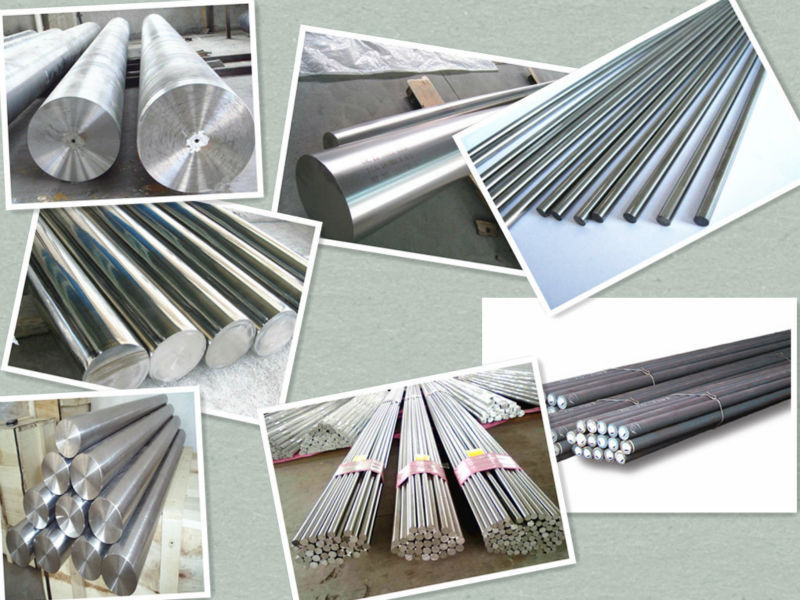

- Surface Treatment Bright, Black, Ground Finished

- Dimensions Customized; Available in strips, rods, and blocks

- Type High Speed Steel

- Standard IS: 7291:2007, DIN 1.3243, ISO 3350, BS: S705

- Thickness 0.5mm to 100mm

- Steel Type Alloy Steel

- Shape Flat, Round, Square

- Click to View more

X

HSS M35 Price And Quantity

- 50 INR

- 500 Kilograms

HSS M35 Product Specifications

- Bright, Black, Ground Finished

- High Speed Steel

- Customized; Available in strips, rods, and blocks

- IS: 7291:2007, DIN 1.3243, ISO 3350, BS: S705

- 0.5mm to 100mm

- Alloy Steel

- Flat, Round, Square

- M35

- Cutting tools, drills, taps, milling tools

- HSS M35 (High Speed Steel with 5% Cobalt)

- 0.01mm

- Hot Rolled/Forged/Annealed

HSS M35 Trade Information

- 100000 Kilograms Per Month

- 1 Days

Product Description

Introducing the latest HSS M35, engineered for kingly performance at an unbeatable price. With a dazzling hardness range of 62-65 HRC post-heat treatment and a high cobalt content (4.50%-5.00%), this first-rate alloy steel offers excellent heat resistance up to 600C. Boasting a density of 8.3 g/cm and unbeatable machinability, our HSS M35 meets leading standards (IS: 7291:2007, DIN 1.3243, ISO 3350, BS: S705). Supplied at the lowest price, its available in strips, rods, or blocks with customized dimensions and precise surface treatments. Exported from India, packed securely, and perfect for precision tool applications.

Versatile Applications of HSS M35

HSS M35 is widely employed by manufacturers and engineers for cutting tools, drills, taps, and milling tools in industrial sectors. Used as a high-performance material, it serves experts in metalworking, automotive, and aerospace industries who require reliable alloy steel with remarkable heat resistance and machinability. Available in customized shapes and sizes, HSS M35 is preferred for its durability and superior cutting capabilities.

Sample Policy, Supply, and Certifications

Our HSS M35 is supported by a sample policy catering to export market inquiries, ensuring buyers receive evaluated materials prior to bulk order processing. With top-tier certifications (IS, DIN, ISO, BS), supply ability is robust and consistent. Competitive sale prices are offered to position Indian manufacturers, exporters, and suppliers strongly in global markets. Orders are processed swiftly with secure packaging to guarantee product integrity.

Versatile Applications of HSS M35

HSS M35 is widely employed by manufacturers and engineers for cutting tools, drills, taps, and milling tools in industrial sectors. Used as a high-performance material, it serves experts in metalworking, automotive, and aerospace industries who require reliable alloy steel with remarkable heat resistance and machinability. Available in customized shapes and sizes, HSS M35 is preferred for its durability and superior cutting capabilities.

Sample Policy, Supply, and Certifications

Our HSS M35 is supported by a sample policy catering to export market inquiries, ensuring buyers receive evaluated materials prior to bulk order processing. With top-tier certifications (IS, DIN, ISO, BS), supply ability is robust and consistent. Competitive sale prices are offered to position Indian manufacturers, exporters, and suppliers strongly in global markets. Orders are processed swiftly with secure packaging to guarantee product integrity.

FAQs of HSS M35:

Q: How is HSS M35 utilized in industrial applications?

A: HSS M35 is primarily used to manufacture cutting tools, drills, taps, and milling machines, offering excellent performance in high-speed metalworking environments due to its heat resistance and strength.Q: What benefits does the cobalt addition in HSS M35 provide?

A: The inclusion of 4.5% to 5.0% cobalt significantly enhances heat resistance, hardness, and wear properties, allowing tools made from HSS M35 to perform consistently at elevated temperatures.Q: When should I choose HSS M35 over other high-speed steels?

A: Select HSS M35 when your application requires superior hardness, extended tool life, and operation at high temperatures, particularly in demanding machining or cutting processes.Q: Where can I order customized HSS M35 products?

A: You can order HSS M35 in customized dimensions directly from our facility in India. We export globally, delivering strips, rods, and blocks as per your specifications.Q: What is the process for ordering HSS M35 samples and bulk supply?

A: Request samples by contacting our sales team for evaluation. Once approved, bulk order processing begins with quality checks, competitive sale pricing, and secure packaging for shipment.Q: What certifications does your HSS M35 comply with?

A: Our HSS M35 is certified to IS: 7291:2007, DIN 1.3243, ISO 3350, and BS: S705, assuring you of international standard quality and reliable performance in all supplied products.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email