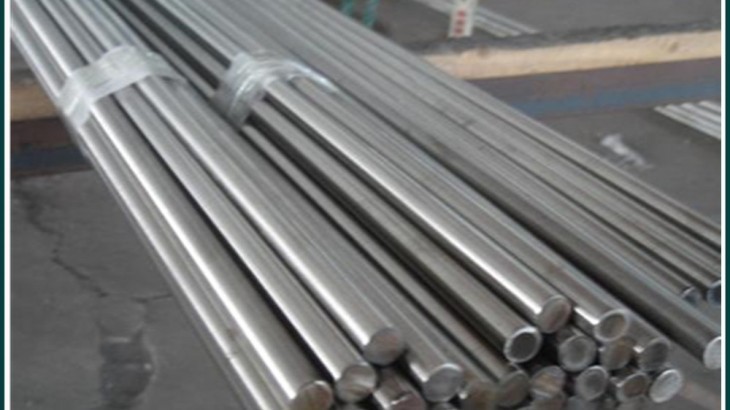

SS 303 Bright Bar

50 INR

Product Details:

- Standard ASTM A582, ASTM A276

- Technics Cold Drawn / Cold Finished

- Application Automobile, Fasteners, Shafts, Precision Components, Engineering

- Tolerance h9, h11, or as specified

- Type Bright Bar

- Shape Round, Square, Hexagonal

- Surface Treatment Bright, Polished

- Click to View more

X

SS 303 Bright Bar Price And Quantity

- 500 Kilograms

- 50 INR

SS 303 Bright Bar Product Specifications

- ASTM A582, ASTM A276

- Cold Drawn / Cold Finished

- Automobile, Fasteners, Shafts, Precision Components, Engineering

- Bright Bar

- h9, h11, or as specified

- Round, Square, Hexagonal

- Bright, Polished

- Austenitic

- SS 303

- Diameter: 3mm to 100mm, Length: up to 6 meters (customizable)

- Customized as per requirement

- Stainless Steel

SS 303 Bright Bar Trade Information

- 100000 Kilograms Per Month

- 1 Days

Product Description

We are reputed as one of the leading Stainless Steel Round Bars Manufacturers, Exporters and Suppliers from Maharashtra, India. With the help of our ultra-modern facility, we are able to manufacture our SS 303 Bright Bars in variety of shapes, sizes and specifications as per the buyer is requirements. They are widely used in several industries like automobile, electric motor, railways, defense, shaft making, agriculture, health & sports, and many more. We welcome queries for bulk orders from India and abroad for SS 303 Bright Bars.

Grades :

Grades :

- AISI : 201, 202, 301, 302, 303, 304, 304H, 304L, 316, 316H, 316L, 309, 309S, 310, 310S, 316Ti, 317, 317L, 347, 321, 321H, 410, 416, 420, 430, 430F, 431, 440C, 630, 17-4PH, F51

- Size: 3mm to 100mm

- Length: 1000mm to 6000mm

Ultra Bright Finish with Exceptional Quality

SS 303 Bright Bars undergo specialized surface treatment to achieve a highly reflective, mirror-like finish along with polished smoothness. The finish enhances not only aesthetics but also contributes to additional corrosion resistance, making these bars suitable for visible components in industries where appearance matters as much as durability.

Superior Performance and Machinability

Engineered for precision, SS 303 Bright Bars exhibit a unique balance of mechanical propertiesstrength, hardness, and ductility. The enhanced machinability allows for efficient and cost-effective processing into complex components, benefiting manufacturers and end-users engaged in high-volume production or custom engineering solutions.

Versatile Shape and Dimension Customization

Available in round, square, and hexagonal profiles, these bright bars can be customized in thickness, length, and tolerance (h9, h11, or as specified) to fit diverse project needs. From automotive shafts to intricate fasteners, the dimensional flexibility ensures seamless integration into varied applications.

FAQs of SS 303 Bright Bar:

Q: How are SS 303 Bright Bars manufactured to achieve the ultra bright mirror finish?

A: These bars are produced through cold drawn or cold finished techniques, followed by advanced bright and polished surface treatments. This process endows the bars with a mirror-like reflective appearance combined with a smooth, high-quality surface, making them ideal for both functional and decorative uses.Q: What makes SS 303 Bright Bars particularly suitable for machining operations?

A: SS 303 Bright Bars are engineered with superior machinability, rated at 78%, which means they can be shaped and cut more efficiently than most other stainless steels. This attribute reduces tool wear and machining time, ensuring cost-effective manufacturing of precision components.Q: When should SS 303 Bright Bars be chosen for applications over other stainless steel grades?

A: These bars are most beneficial in environments where mild corrosion resistance, excellent machinability, and a polished finish are required, such as in the production of fasteners, shafts, and intricate engineering parts. For highly corrosive or marine settings, alternative grades may be recommended.Q: Where can SS 303 Bright Bars be utilized?

A: They are widely used in the automotive industry, precision engineering, fastener manufacturing, as well as for producing shafts and other components where accuracy, high finish, and easy machining are critical. Their adaptability suits both high-volume and customized projects.Q: What are the benefits of the standard export packaging offered with SS 303 Bright Bars?

A: The bars are packed in bundles or wooden cases according to international export norms, ensuring protection from physical damage and corrosion during transit. This reliable packaging is essential for maintaining quality, especially for international shipments.Q: Can the dimensions and tolerances of SS 303 Bright Bars be customized?

A: Yes, these bright bars are available in diameters from 3mm to 100mm and lengths up to 6 meters, with customizable tolerances such as h9 or h11, or as specified by clients. Thickness and shape (round, square, hexagonal) can also be tailored to project requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email