SS 410

50 INR

Product Details:

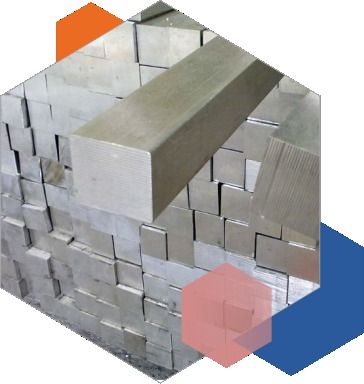

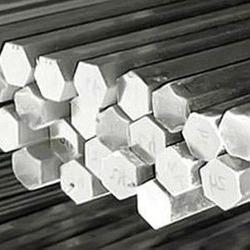

- Shape Sheets, Plates, Coils, Bars

- Application Construction, Fabrication, Automobile, Petrochemical, Oil & Gas

- Thickness 0.5 mm to 100 mm

- Type Stainless Steel

- Tolerance +/- 0.02 mm

- Technics Hot Rolled, Cold Rolled

- Dimensions Custom sizes as per requirement

- Click to View more

X

SS 410 Price And Quantity

- 500 Kilograms

- 50 INR

SS 410 Product Specifications

- 0.5 mm to 100 mm

- Hot Rolled, Cold Rolled

- Custom sizes as per requirement

- Martensitic Stainless Steel

- Construction, Fabrication, Automobile, Petrochemical, Oil & Gas

- Sheets, Plates, Coils, Bars

- +/- 0.02 mm

- 410

- SS 410

- Polished, Hot Rolled, Cold Rolled

- ASTM A240, ASTM A276, ASTM A479

- Stainless Steel

SS 410 Trade Information

- 100000 Kilograms Per Month

- 1 Days

Product Description

Discover the trending elite choice in stainless steelSS 410. Engineered as a noble masterpiece of metallurgical innovation, SS 410 offers unparalleled strength with a Rockwell B82 maximum hardness, yield strength of approx. 275 MPa, and tensile strength of approx. 450 MPa. This magnetic martensitic stainless steel is corrosion-resistant in mild environments and boasts exceptional durability with a melting point up to 1510C. Featuring a range of polished finishes and custom sizes, it adapts seamlessly for construction, fabrication, automobile, petrochemical, and oil & gas sectors. Explore excellence with our expert exporting, manufacturing, and supply from India.

SS 410: Surface Versatility and Applications

SS 410 stands out for its superior surface finish options2B, BA, No.1, No.4, Mirrorand robust applicability. It is widely used on various application surfaces from construction frameworks to automobile panels and petrochemical equipment. Its commercial uses include architectural cladding, fabrication of durable components, and oil & gas infrastructure. With polished and treated surfaces, SS 410 not only enhances visual appeal but also ensures long-term performance in demanding operating conditions.

Sample Policy and Global Supply Reach of SS 410

We ensure a seamless supply of SS 410 samples to facilitate your material selection process. Samples are handed over promptly to interested clients to enable effective evaluation. Our main domestic market spans across India, while our primary export markets cover Asia, the Middle East, and global destinations. Orders are efficiently dispatched, ensuring timely delivery and continuous support for international and domestic clients alike.

SS 410: Surface Versatility and Applications

SS 410 stands out for its superior surface finish options2B, BA, No.1, No.4, Mirrorand robust applicability. It is widely used on various application surfaces from construction frameworks to automobile panels and petrochemical equipment. Its commercial uses include architectural cladding, fabrication of durable components, and oil & gas infrastructure. With polished and treated surfaces, SS 410 not only enhances visual appeal but also ensures long-term performance in demanding operating conditions.

Sample Policy and Global Supply Reach of SS 410

We ensure a seamless supply of SS 410 samples to facilitate your material selection process. Samples are handed over promptly to interested clients to enable effective evaluation. Our main domestic market spans across India, while our primary export markets cover Asia, the Middle East, and global destinations. Orders are efficiently dispatched, ensuring timely delivery and continuous support for international and domestic clients alike.

FAQs of SS 410:

Q: How can SS 410 benefit my fabrication or construction project?

A: SS 410 provides a combination of mechanical strength, good corrosion resistance, and appealing surface finishes, making it ideal for applications in construction, fabrication, and industrial sectors. Its versatility enhances both structural integrity and aesthetics.Q: What is the standard process for supplying and dispatching SS 410?

A: Once an order is confirmed, SS 410 is prepared in the required shape and finish, then efficiently dispatched to the clients destination. We ensure careful handling and timely delivery for both domestic and international orders.Q: Where can custom sizes and finishes of SS 410 be sourced?

A: Custom sizes and surface finishes can be sourced directly from us, the manufacturer and exporter based in India, catering to your specific requirements in sheets, plates, coils, or bars with tolerances as tight as +/- 0.02 mm.Q: When should you opt for SS 410 in commercial applications?

A: Select SS 410 when you require a martensitic stainless steel that offers a balance of hardness, machinability, and corrosion resistance, particularly in mild atmospheric or chemical environments and where magnetic properties are advantageous.Q: What are the primary usage and application surfaces for SS 410?

A: SS 410 is primarily used on surfaces exposed to mechanical wear or requiring reliable corrosion resistance, such as architectural facades, industrial machinery, automobile parts, and petrochemical vessels.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email