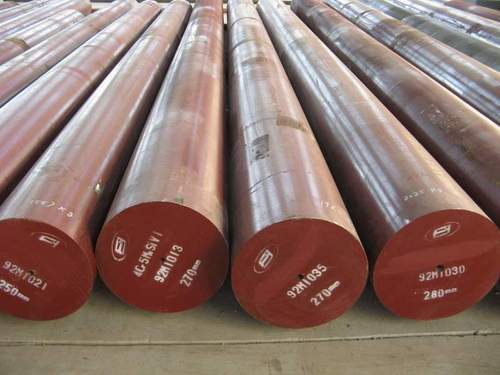

Alloy Steel Bar

52 INR

Product Details:

- Grade EN8, EN19, EN24, EN31, 42CrMo4, 4140, 4340

- Technics Hot Rolled, Forged, Cold Drawn

- Thickness 10 mm to 600 mm

- Steel Type High Strength Alloy Steel

- Application Construction, Engineering, Automotive, Oil & Gas, Machinery

- Tolerance H8, H9, H10 as per international standards

- Material Alloy Steel

- Click to View more

X

Alloy Steel Bar Price And Quantity

- 52 INR

- 500 Kilograms

Alloy Steel Bar Product Specifications

- Round, Square, Hexagonal, Flat

- Construction, Engineering, Automotive, Oil & Gas, Machinery

- Hot Rolled / Cold Rolled

- H8, H9, H10 as per international standards

- Diameter 10 mm to 600 mm, Length up to 6000 mm

- ASTM A182 / A479, IS, EN, JIS, DIN

- High Strength Alloy Steel

- 10 mm to 600 mm

- Alloy Steel

- Hot Rolled, Forged, Cold Drawn

- EN8, EN19, EN24, EN31, 42CrMo4, 4140, 4340

- Polished, Black, Bright

Alloy Steel Bar Trade Information

- 100000 Kilograms Per Month

- 1 Days

- Yes

- Sample costs shipping and taxes has to be paid by the buyer

- All India

Product Description

We, Righton Impex, are a well known manufacturer, exporter and supplier of Alloy Steel Bars. The offered bars are manufactured at our advanced production unit by utilizing the best quality steel. These bars are used in various industry like construction, military, ship building, etc. In addition to this, our valued clients can avail this Alloy Steel Bars from us at reasonable prices.

Features:

- High strength

- Accurate dimensions

- Resistant to corrosion

- Sturdiness

Versatile Application Range

Alloy steel bars can be used across a wide spectrum of industries, including automotive, construction, oil & gas, engineering, and heavy machinery. Their high tensile strength and excellent durability make them reliable components in structural supports, shafts, gears, and mechanical parts requiring robust performance under demanding conditions.

Precision Manufacturing and Customization

Produced using hot rolled, forged, and cold drawn techniques, these steel bars offer precise tolerance levels (H8, H9, H10) and customizable hardness. Lengths and diameters can be tailored per project requirements, and surface treatments such as polished, black, and bright finishes enhance their suitability for specialized applications.

Compliance and Quality Assurance

Alloy steel bars comply with international standards including ASTM A182 / A479, IS, EN, JIS, and DIN, ensuring product quality and reliability. The delivery conditions and packing can be customized to meet export requirements, while material grades are selected to optimize corrosion resistance and mechanical properties for critical uses.

FAQs of Alloy Steel Bar:

Q: How are alloy steel bars manufactured for precise tolerances and high strength?

A: Alloy steel bars are produced using hot rolled, cold drawn, or forged methods, enabling fine control over dimensions and tolerances down to H8, H9, or H10 as specified in international standards. Heat treatment processes such as annealing, normalizing, and quenching & tempering further enhance the bars mechanical properties and strength as per client requirements.Q: What applications are alloy steel bars suitable for?

A: Alloy steel bars are widely used in construction, engineering, automotive, oil & gas, and machinery industries. Their high tensile strength and durability make them ideal for components like shafts, gears, fasteners, and structural supports subjected to heavy loads and stresses.Q: When is heat treatment required for alloy steel bars and what options are available?

A: Heat treatment is applied to alloy steel bars when specific mechanical properties or hardness are needed for an application. Options include annealing, normalizing, and quenching & tempering, and can be customized according to the clients specification and grade, with hardness available up to 35 HRC or as required.Q: Where can alloy steel bars be exported from and what packing options are provided?

A: Alloy steel bars are exported from India and supplied globally. Packaging is tailored for secure export, using standard export-worthy materials or customized packing as specified by the customer to ensure safe transportation and delivery.Q: What is the process for ordering customized alloy steel bars by dimensions or surface treatment?

A: Customers can specify desired dimensions (diameter, length, thickness), shape (round, square, hexagonal, flat), surface finish (mill finish, peeled, ground, polished, bright, black), and grade. The bars are manufactured accordingly, meeting international standards and delivered as per the agreed delivery condition and packing.Q: How do users benefit from the corrosion resistance and machinability of alloy steel bars?

A: Alloy steel bars offer good corrosion resistance depending on their alloy content, making them suitable for applications exposed to moisture or chemicals. Their excellent machinability and weldability reduce processing time and costs, enabling efficient fabrication for a variety of uses.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email