HOT DIE STEEL H13

50 INR

Product Details:

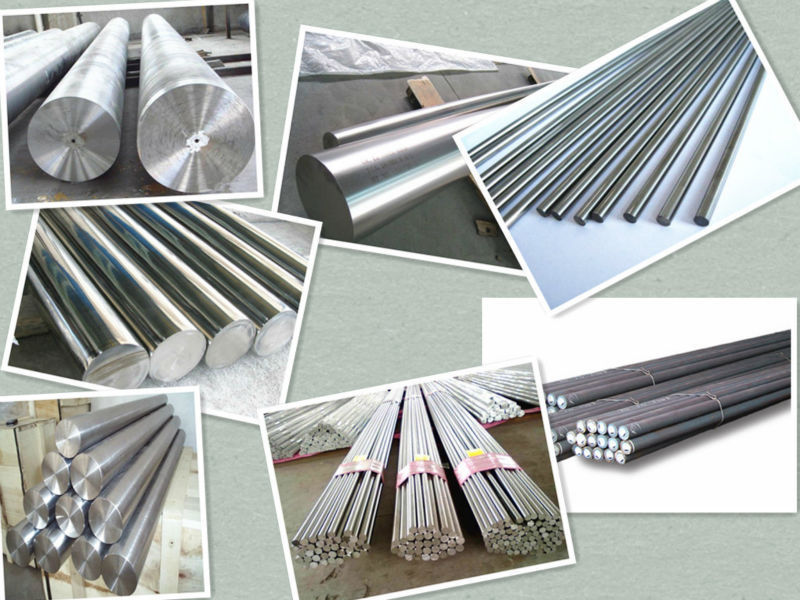

- Surface Treatment Black, Bright, Peeled, Forged, Annealed

- Shape Rounds, Flats, Blocks, Squares

- Tolerance Precision machined, as per customer specification or industry standard

- Grade H13

- Dimensions Available in rounds, flats, and squares; custom sizes on request

- Type Hot Die Steel

- Standard DIN 1.2344, AISI H13, EN X40CrMoV5-1, JIS SKD61

- Click to View more

X

HOT DIE STEEL H13 Price And Quantity

- 500 Kilograms

- 50 INR

HOT DIE STEEL H13 Product Specifications

- Rounds, Flats, Blocks, Squares

- Precision machined, as per customer specification or industry standard

- H13

- Alloy Steel (H13)

- Black, Bright, Peeled, Forged, Annealed

- Die making, hot working tools, extrusion dies, forging dies, die casting dies, plastic moulds

- Tool Steel

- 8 mm to 400 mm (as per requirement)

- Hot Rolled, Forged, Annealed

- Hot Die Steel

- DIN 1.2344, AISI H13, EN X40CrMoV5-1, JIS SKD61

- Available in rounds, flats, and squares; custom sizes on request

HOT DIE STEEL H13 Trade Information

- 100000 Kilograms Per Month

- 1 Days

Product Description

HOT DIE STEEL H13 has procured favorable reviews for its enlightened engineering and extraordinary durability. Delivered in the annealed condition at a maximum of 229 HB, it is suitable for achieving a glorious 44-52 HRC after heat treatment. With a density of approximately 7.80 g/cm, this versatile alloy is available in various shapesrounds, flats, and blockswith precision machining as per customer specifications. Reduced thermal fatigue and shock, along with moderate corrosion resistance, make it optimal for hot working tools. Each batch undergoes rigorous checks, ensuring world-class quality and reliability.

Application & Competitive Edge of HOT DIE STEEL H13

Used extensively in die making and tooling for extrusion, forging, and die casting, HOT DIE STEEL H13 is celebrated for its favorable reviews and extraordinary toughness. Its primary advantages include reduced wear under thermal stress, glorious machinability in the annealed state, and consistent performance across custom shapes and dimensions. Enlightened material selection ensures high resistance to shock, making it a reputable choice for demanding manufacturing environments.

Supply Capability, Market Reach & Compliance

HOT DIE STEEL H13 is available throughout India, supported by trustworthy goods transport solutions and strategic transport services to ensure timely delivery of every order. We maintain a competitive list price without compromising on complianceour products are certified as per DIN 1.2344, AISI H13, EN X40CrMoV5-1, and JIS SKD61 standards. Our supply ability meets robust demand with efficient fulfillment across major domestic markets and prompt response to custom requirements.

Application & Competitive Edge of HOT DIE STEEL H13

Used extensively in die making and tooling for extrusion, forging, and die casting, HOT DIE STEEL H13 is celebrated for its favorable reviews and extraordinary toughness. Its primary advantages include reduced wear under thermal stress, glorious machinability in the annealed state, and consistent performance across custom shapes and dimensions. Enlightened material selection ensures high resistance to shock, making it a reputable choice for demanding manufacturing environments.

Supply Capability, Market Reach & Compliance

HOT DIE STEEL H13 is available throughout India, supported by trustworthy goods transport solutions and strategic transport services to ensure timely delivery of every order. We maintain a competitive list price without compromising on complianceour products are certified as per DIN 1.2344, AISI H13, EN X40CrMoV5-1, and JIS SKD61 standards. Our supply ability meets robust demand with efficient fulfillment across major domestic markets and prompt response to custom requirements.

FAQs of HOT DIE STEEL H13:

Q: How is HOT DIE STEEL H13 processed before delivery?

A: HOT DIE STEEL H13 is delivered in an annealed, forged, or hot rolled condition, and further machined to meet specified tolerances, ensuring excellent readiness for your application.Q: What benefits does HOT DIE STEEL H13 offer in hot working applications?

A: The steel provides glorious resistance to thermal fatigue and shock, reduced wear, and enlightened machinability, making it ideal for extrusion and forging dies as well as die casting and plastic moulding tools.Q: Where can I procure HOT DIE STEEL H13 in custom sizes or shapes?

A: Custom sizes and shapes such as rounds, flats, blocks, and squares are available upon request from reputable exporters, manufacturers, and suppliersparticularly across major markets in India.Q: What distinguishes the machinability of HOT DIE STEEL H13?

A: In its annealed state, H13 presents extraordinary machinability, allowing for efficient cutting, shaping, and forming to match demanding industrial specifications.Q: When should HOT DIE STEEL H13 be heat-treated for optimal performance?

A: Heat treatment is recommended after the initial shaping to achieve the desired hardness range of 44-52 HRC, enhancing its durability for long-term use in high-stress environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email