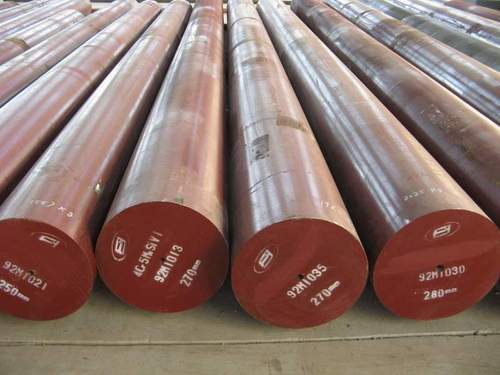

EN 8 STEEL BARS

48 INR

Product Details:

- Material Carbon Steel

- Dimensions Customised as per requirement, commonly available in 10 mm 600 mm diameter

- Steel Type Medium Carbon Steel

- Thickness As per customer requirement

- Application Automobile Parts, Shafts, Gears, General Engineering, Machinery Parts

- Technics Hot Rolled / Cold Drawn

- Type Steel Bar

- Click to View more

X

EN 8 STEEL BARS Price And Quantity

- 500 Kilograms

- 48 INR

EN 8 STEEL BARS Product Specifications

- Automobile Parts, Shafts, Gears, General Engineering, Machinery Parts

- As per customer requirement

- Medium Carbon Steel

- Customised as per requirement, commonly available in 10 mm 600 mm diameter

- Carbon Steel

- Round, Square, Hexagonal, Rectangular

- H8, H9, H11 or as specified

- EN 8

- Polished, Bright, Black

- EN 8 (080M40)

- Hot Rolled / Cold Drawn

- Steel Bar

EN 8 STEEL BARS Trade Information

- 100000 Kilograms Per Month

- 1 Days

Product Description

Avail the Elite Deal on EN 8 Steel Bars, crafted for unassailable performance and flawless reliability in heavy-duty applications. With a brilliant combination of strength (Ultimate Tensile: 550800 MPa, Yield: >450 MPa) and good machinability, these medium carbon steel bars offer impeccable versatility. Available in limited stock, with dimensions customisable from 2 to 6 meters length and 10 to 600 mm diameter, each piece exhibits unmatched durability with a polished or bright finish. Standard equivalents include DIN C40 and AISI 1040. Our bars provide moderate corrosion resistance, with induction and case hardening options, making them ideal for elite engineering projects.

Competitive Edge and Application Versatility

EN 8 Steel Bars hold a distinct advantage with their superior toughness and reliable elongation, exceeding 16%. Praised for their good machinability and weldability, these bars are flawless for automobile parts, gears, shafts, and general engineering machinery. The availability in various shapesround, square, hexagonal, and rectangularcoupled with customization options, grants users an unassailable edge in competitive industrial settings. Their moderate corrosion resistance allows for a protective coating, optimizing long-term usage.

Domestic Presence and Export Opportunities

EN 8 Steel Bars enjoy considerable demand in Indias main domestic market, with a steady drop-off in list price as volumes increase. As leading exporters, manufacturers, and suppliers, our asking price aligns with international standards, catering to main export markets across Asia, Europe, and the Middle East. Products are efficiently shipped via major Indian FOB ports, ensuring rapid and reliable delivery. This broad trade network guarantees accessibility for both local and global clients.

Competitive Edge and Application Versatility

EN 8 Steel Bars hold a distinct advantage with their superior toughness and reliable elongation, exceeding 16%. Praised for their good machinability and weldability, these bars are flawless for automobile parts, gears, shafts, and general engineering machinery. The availability in various shapesround, square, hexagonal, and rectangularcoupled with customization options, grants users an unassailable edge in competitive industrial settings. Their moderate corrosion resistance allows for a protective coating, optimizing long-term usage.

Domestic Presence and Export Opportunities

EN 8 Steel Bars enjoy considerable demand in Indias main domestic market, with a steady drop-off in list price as volumes increase. As leading exporters, manufacturers, and suppliers, our asking price aligns with international standards, catering to main export markets across Asia, Europe, and the Middle East. Products are efficiently shipped via major Indian FOB ports, ensuring rapid and reliable delivery. This broad trade network guarantees accessibility for both local and global clients.

FAQs of EN 8 STEEL BARS:

Q: How can EN 8 Steel Bars be customized to meet specific project requirements?

A: EN 8 Steel Bars can be manufactured in lengths ranging from 2 to 6 meters, with diameters between 10 mm and 600 mm, and various shapes such as round, square, hexagonal, or rectangular, meeting custom specifications.Q: What process ensures the flawless finish of EN 8 Steel Bars?

A: The bars undergo advanced surface treatments like polishing, bright finishing, or black finishing, and are delivered in annealed, normalized, peeled, or polished conditions to guarantee a flawless look and quality.Q: When should additional protective finishing be applied to EN 8 Steel Bars?

A: A protective coating should be applied during installation in corrosive or outdoor environments to enhance moderate corrosion resistance and ensure long-term performance.Q: Where are EN 8 Steel Bars predominantly used in industry?

A: These bars are widely utilized in the manufacture of automobile parts, shafts, gears, and machinery components within general engineering and industrial sectors.Q: What are the main benefits of using EN 8 Steel Bars for manufacturing?

A: EN 8 Steel Bars provide robust strength, good machinability, customizable shapes and sizes, and reliable elongation. These attributes make them brilliant for demanding engineering and fabrication projects.Q: How does the machinability of EN 8 Steel Bars support industrial production?

A: EN 8 Steel Bars have good machinability and weldability, which allows for efficient processing on CNC machines and facilitates complex manufacturing tasks in industrial environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Email

Send Email