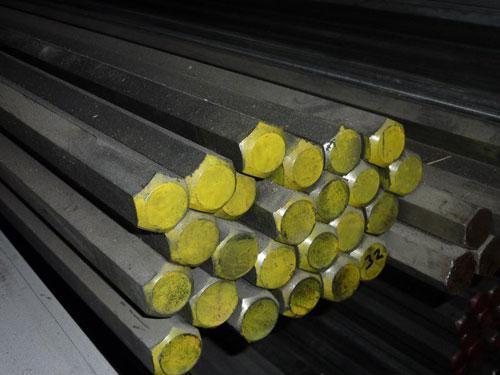

Hexagonal Steel Bright Bars

Product Details:

- Tolerance h11, h12 or as per specific standards

- Surface Treatment Bright, Smooth Finish

- Technics Cold Drawn / Peeled / Polished

- Type Bright Bar

- Dimensions 6mm to 60mm across flats (AF)

- Shape Hexagonal

- Grade EN1A, EN8, EN9, EN24, EN31, 304, 316, 410, 420, IS2062, A105, etc.

- Click to View more

Hexagonal Steel Bright Bars Price And Quantity

- 50 INR

- 500 Kilograms

Hexagonal Steel Bright Bars Product Specifications

- Mild Steel, Alloy Steel, Stainless Steel

- Automobile Parts, Fasteners, Engineering Components, Shafts, Construction, Heavy Equipment

- ASTM A276, AISI, DIN, EN, JIS, IS, BS

- Mild Steel / Carbon Steel / Alloy Steel / Stainless Steel

- 6mm to 60mm across flats (AF)

- Hexagonal

- Customized as per requirements

- EN1A, EN8, EN9, EN24, EN31, 304, 316, 410, 420, IS2062, A105, etc.

- Cold Drawn / Peeled / Polished

- Bright Bar

- h11, h12 or as per specific standards

- Bright, Smooth Finish

Hexagonal Steel Bright Bars Trade Information

- 100000 Kilograms Per Month

- 1 Days

Product Description

We have marked a unmatchable position in the market by manufacturing, exporting and supplying a precisely engineered range of Hexagonal Steel Bright Bars. The offered bars are manufactured by our experienced professionals by fine grade raw materials and modular machines. The provided bars are used in engineering, machine building, automotive and many more industry. In order to meet the diverse needs of our client, we are manufacturing these bars in a range of dimensions. Clients can purchase these Hexagonal Steel Bright Bars from us at market leading prices.

Key Features:

- Optimum durability

- Accurate dimension

- High strength

- Rust proof

- Avail in a varied dimensions

Specifications:

-

IS: 11C10S25, 40C10S18

-

EN: EN1A, EN1A(L), EN8M, EN15AM

-

DIN: 9SMn28, 11SMnPb30

-

AISI/SAE: 1213, 1214, 12L14

-

Size: 4mm to 60mm

-

Length: 1000mm to 6000mm

Precision Engineering and Customization

Hexagonal Steel Bright Bars are manufactured using state-of-the-art techniques like cold drawing and polishing, which deliver remarkable dimensional accuracy and sharp, well-defined edges. Custom lengths, thicknesses, and tolerances can be tailored according to specific project requirements, while surface treatments enhance both appearance and durability. This makes them suitable for a range of specialized engineering and automotive applications.

Superior Mechanical Properties

With the choice of annealed or hardened delivery conditions, and a range of hardness depending on the grade selected, these steel bright bars deliver dependable performance under demanding conditions. Their bright, smooth surface finish and high corrosion resistanceespecially in stainless steel varietiesensure longevity and reliability in end-use applications such as shafts, fasteners, and machinery components.

FAQs of Hexagonal Steel Bright Bars:

Q: How are Hexagonal Steel Bright Bars typically manufactured and what processes are involved?

A: Hexagonal Steel Bright Bars are produced using advanced techniques such as cold drawing, peeling, and polishing. Depending on specifications, they may also be annealed or hardened. These processes enhance dimensional accuracy, deliver a bright surface, and ensure the materials mechanical properties meet the required standards.Q: What sizes and dimensional tolerances are available for these bright bars?

A: The bars are supplied in standard lengths ranging from 3 to 6 meters, with cross-sectional dimensions from 6mm to 60mm across flats. Custom thicknesses and lengths can be provided, and tolerances such as h11 and h12 or others according to specific standards are available to fit various engineering needs.Q: When is high corrosion resistance guaranteed in these bars?

A: High corrosion resistance is ensured when the bars are manufactured from stainless steel grades, such as 304, 316, 410, and 420. These grades are particularly suitable for environments or applications where exposure to moisture or corrosive agents is expected.Q: Where are Hexagonal Steel Bright Bars commonly used?

A: These bars find application in automotive parts, fasteners, shafts, engineering components, construction, and heavy equipment. Their precision, strength, and surface finish make them ideal for both structural and functional uses in these sectors.Q: What are the benefits of choosing bright drawn bars over regular steel bars?

A: Bright drawn bars offer superior surface finish, tighter dimensional tolerances, and enhanced mechanical properties. They come with sharp, precise edges, making them easier to machine or assemble. Their bright appearance also reduces the need for further finishing in many applications.Q: How is the packaging and delivery of these steel bars handled?

A: Hexagonal Steel Bright Bars are typically bundled and wrapped with plastic or HDPE to protect them during transport. Packaging can be customized according to customer specifications to ensure safe and efficient delivery.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Email

Send Email